Drilling: A gap is drilled deep into the ground to support the micropile, reaching stable soil or rock levels.

Capacities range dependant upon the micropile dimensions and subsurface profile. Allowable compressive capacities of over 500 tons are actually realized.

Micropiles offer a large-potential, lower-disturbance foundation Option, especially in complicated soil problems or confined spaces. Regardless of whether you’re retrofitting an present structure or working with unstable soil, micropiles offer you a versatile and dependable choice for Basis stabilization.

Log in to TheConstructor to request thoughts, reply people today’s queries, write article content & connect with Others. When you be a part of you get more Added benefits.

They are handy for installation in ecologically demanding settings, for instance wind turbine towers, as they could be set by means of approximately any ground affliction.

Micropiles have been around for over 4 decades and have become an significantly well known Remedy to stabilizing soft soils and Assembly the needs of job proprietors who need to have more space on which to develop.

Should your details contains values รับตอกเสาเข็มไมโครไพล์ ราคาถูก which are deemed Subtotals or Totals, which include Net Profits, you are able to set Those people values so they start about the horizontal axis at zero And do not "float".

In much larger micropile designs, casing diameter is minimized because the successful Internet place readily available for reinforcement is optimized with a single greater bar compared to more compact bundled bars (see illustration).

The casing may possibly access The full size in the pile, or it may just increase a portion of the duration, While using the reinforcing bar บริการรับตอกเสาเข็มไมโครไพล์หาดใหญ่ extending the complete length.

Most important grout is completed under pressure and after coagulation, secondary grout is concluded by way of put in sleeve ports.

Potential differs in accordance on micropile dimensions and subsurface topography, but compressive capacities of about five hundred tons are attained.

The hollow threaded rebar procedure is also known as a self-drilling hollow bar method. In This technique, the hollow bar can functionality for a sacrificial drill bit. It gets transformed into a central reinforcement. It can be utilized to flush out the particles. This technique can remove pre-drilling and Regular removal of pipes and drills.

They have got a higher load capacity and a functionality to resist compressive, tensile, and lateral masses.

In many scenarios, They might function an incredibly economical alternative for more concerned but powerful Basis programs.

Rider Strong Then & Now!

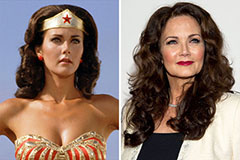

Rider Strong Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!